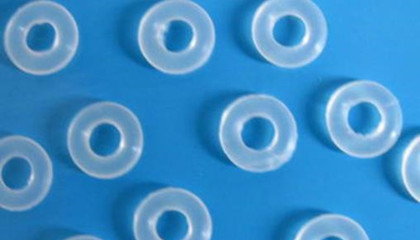

Although the coated O-ring is easy to use, it is crucial to grasp the correct groove size standard for its sealing performance and service life during use. This paper will introduce the dimension standard of its groove, and discuss its importance and application.

First, sealing ring groove size standard:

Groove width: The width of the sealing ring groove should be strictly in accordance with the relevant standards or design requirements. If the width is too small, the sealing ring cannot be installed normally, and if the width is too large, the sealing performance of the cake will be affected, resulting in leakage.

Groove depth: The depth of the groove determines the compression and sealing performance of the sealing ring. The groove depth should ensure that the seal ring can be sealed after compression to avoid excessive compression resulting in rupture or deformation.

Fillet radius: The grooves should have an appropriate fillet radius to reduce the risk of stress concentration and damage, while facilitating the installation and removal of the seals.

Other dimensional parameters, including the diameter of the ring groove, the flatness of the bottom, the ratio of the width to the depth of the groove, should also be designed and controlled according to the specific application and standard requirements.

Second, the importance of size standards:

Ensure sealing performance: The correct groove size ensures that the seal ring will fit well with the joint during compression to form a reliable seal. The proper groove size can effectively ensure sealing, avoid leakage and penetration, and thereby protect machinery or equipment from liquid, gas or dust intrusion.

Improve service life: The proper groove size can reduce the stress and deformation of the seal ring, extending its service life. Reasonable groove size can also reduce wear and damage, improve the reliability and stability of the sealing system.

Compliance with standard requirements: The size standard of the sealing ring groove is based on relevant industry standards and design specifications. Following standard groove sizes ensures that products meet industry requirements and meet performance and safety requirements.

Iii. Application and Implementation:

Mechanical manufacturing: In the field of mechanical manufacturing, the size standard of the sealing ring groove should be determined in combination with the specific mechanical equipment and sealing requirements. In applications including bearing boxes, hydraulic cylinders, valves and pumps, it is necessary to pay attention to the groove size to ensure that it can be used normally.

Automotive industry: In the automotive manufacturing process, the size of the sealing ring groove is directly related to the safety of the vehicle. It may be used in key parts of the engine, transmission, braking and fuel system.

Aerospace: In the aerospace field, the size of the sealing ring groove has strict requirements, and its size standards do not allow for error, the appropriate groove size can ensure that the aircraft fuel system, hydraulic system and air pressure system to maintain normal performance.

It can be known that the size standard of the covered O-ring groove is directly related to the sealing performance and service life. A reasonable groove size not only improves sealing performance and extends service life, but also ensures compliance with relevant industry standards and design specifications.